WHY CHOOSE US

BV and SGS which can provide a strong guarantee for stable quality and reliable performance.

PRODUCTION EQUIPMENT

We have complete production line, including multi-position forming machines, CNC machining centers, automatic tapping machines, automatic intermediate frequency welding machine, heat treatment production lines, and electroplating production line.

TESTING EQUIPMENT

We has set up a quality inspection center with metallographic analyzer, concentricity detector, hardness tester, torsion machine, tensile tester coating thickness tester, salt spray tester, light screening instrument, and automatic thread testing machine.

100% FULL INSPECTION

Our factory adopts 100% full inspection for thread accuracy control, and we test the through gauge and stop gauge one by one through a fully automatic through gauge tester to ensure that all the threads of each product meet international standards.

CERTIFICATION

We have passed ISO9001: 2008, ISO/TS16949: 2009, TUV, and SGS these certification, which can provide a strong guarantee for stable quality and reliable performance.

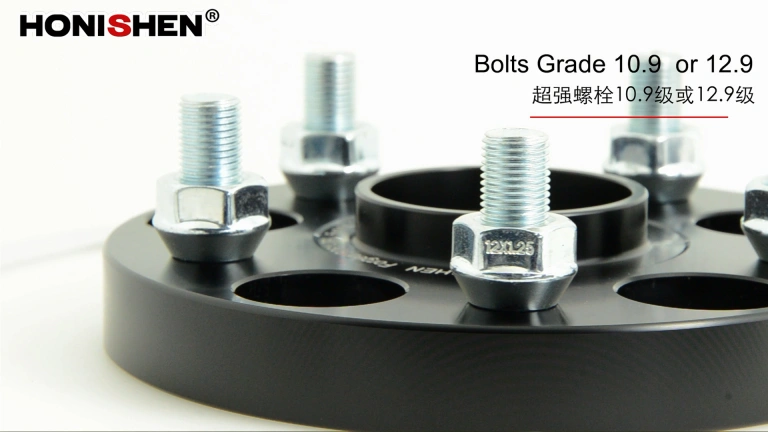

MAIN PRODUCTS

of the professional auto parts manufacturer. The main products are wheel nuts, bolts, spacers, hub centric rings, and socket wrench.

Our company adheres to the business philosophy of "To achieve success through

good quality", constantly optimizes product structure, perfect pre-sales and after

-sales services,and strives to build a first-class "Hongsheng" brand!